Description

Features

● Automatic measurement: Images are captured with CCD and are processed to obtain the angle of response, collapse angle, flat plate angle and other results.

● Patented rotary vibration technology to ensure smooth surface of the powder and to improve measurement accuracy

● Multiple control units meet different needs: Users can control the instrument with a touch screen, computer or through the mobile phone application.

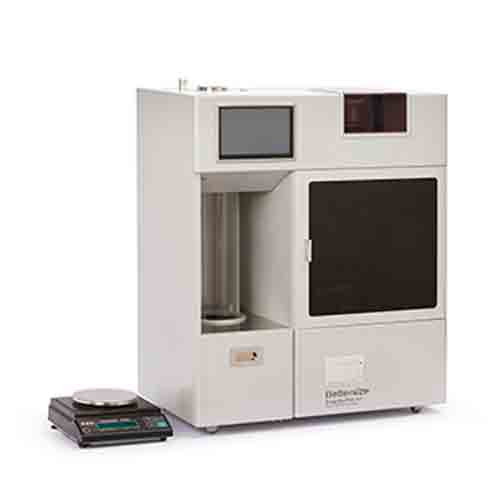

Measurement of tap density and bulk density

Measurement of angle of repose

Specification

| Standard | PowderPro A1 |

| Chinese standard | GB/T16913-2008 4.5, GB/T1479.1-2011, GB/T5162-2006 |

| US standard | ASTM D6393-14 |

| USP | USP32-NF27<616> |

| EP | EP7.0 07/2010:20934 |

| Testing Parameter | |

| Repeatability | ≤3% |

| Drop height | 3mm or 14mm |

| Vibration frequency | 50-300 times per minute (continuous adjustment) |

| Control terminal | Touch screen, mobile and computer |

| System | |

| Dimension | 600mm x 350mm x 730mm (L x W x H) |

| Weight | 42kg |

| Power supply | AC220V, 50/60Hz, 230W |

*The test methods for angle of repose, non-metallic bulk density, tap density, the degree of compression is in line with GB / T 16913-2008-4.5 method

Metal powder and non-metallic powder’s tap density are in line with GB / T 5162-2006 / ISO3953: 1993

**The degree of dispersion, flat angle, uniformity ratio and degree of agglutination are essential to calculating the Carl fluidity index. These parameters are in line with US standards ASTMD6393-08

***Test standards of tap density meet the standards of 07/2010: 20934E of The European Pharmacopoeia EP7.0 and USP 616.

Reviews

There are no reviews yet.