Description

Vertical electric oven

The electric oven consists of a steel structure placed on a frame and including the silica insulation material. Twenty silicon carbide high temperature heating rod elements are placed horizontally in a stack and are grouped in 5 heating zones to provide separate power control.

Replacement of heating elements is fast and easy with no need of refractory maintenance so that oven life is very long. Inner high temperature chamber is protected by a quartz tube. The oven can be equipped, as an option, with a weighing system to provide continuous monitoring of sample weight during reduction test.

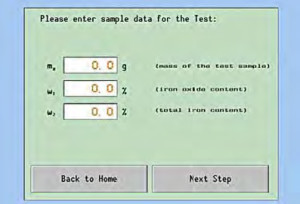

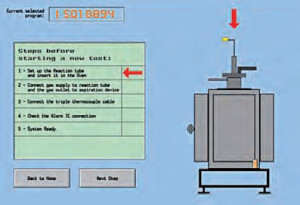

Control Panel

A Multi-Function Control Panel, with function of recorder, viewer and programmer is able to drive oven temperature, gases and other events according to the test procedures.

All the messages, alarms and information on the status of the system are displayed on the Touch Screen unit.

Reaction gases mixes and Nitrogen (purge gas) are driven by electro valves and Mass Flow meter by automatic selection and flow rate control.

|

|

|

|

|

|

|

|

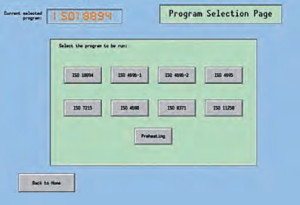

Multifunction and Multistandard capability

The system can be custom tailored according to Customer specific requests and to perform one or more different procedures. Standard procedures, as Reducibility, Relative Reducibility, Disintegration, Decrepitation and Free Swelling, can be selected in below table, where main parameters of processes are listed.

For each standard, proper gas mix line should be included in the control panel and, at same time, proper program, able to automatically drive the test, should be embedded. Moreover, listed of auxiliary devices as continuous weighing system and tumbler can be provided.

| ISO 4696-1 Disintegration |

ISO 4695 Reducibility |

ISO 7215 Relative Reducibility |

ISO 4696-2 Reduction Degradation |

ISO 4698 Free swelling |

ISO 8371 Decrepitation |

ISO 11258 Reducibility Direct Reduction |

IS 10823 Sect.1 B – Static Reduction Degradation |

IS 8167 Reducibility |

IS 11292 Relative Reducibility |

|

| Test Temp. (°C) |

500 | 950 | 900 | 550 | 900 | 700 | 800 | 500 | 950 | 900 |

| Reduction Time (min) |

60 | 240 | 180 | 30 | 60 | 30 | 90 | 60 | 180 | 180 |

| Gas composition Mix |

A | C | B | B | B | — | F | B | B | B |

| Gas flow rate (nl/min) |

20 | 50 | 15 | 15 | 15 | — | 50 | 20 | 15 | 15 |

| Sample mass (g) |

500 | 500 | 500 | 500 | 18 pellets | 500 | 500 | 500±1pc | 500 | 500 |

| Continuous weighing |

Option | Yes | Yes | — | — | — | Yes | Option | Yes | Yes |

| Tumbler TB 3000 | Yes | — | — | Yes | — | — | — | Yes | Yes | — |

Note: MM 6000 can be also equipped with proper hardware and software to run CRI-CSR Test as per ISO 18894, ASTM D 5341 and IS 4023.

| Gas Mix Composition % | |||||

| MIX | N2 | CO | CO2 | H2 | CH4 |

| A | 58 | 20 | 20 | 2 | — |

| B | 70 | 30 | — | — | — |

| C | 60 | 40 | — | — | — |

| F | 10 | 30 | 15 | 45 | — |

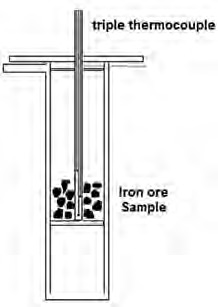

Reaction Vessel

Reaction vessel is constituted of a double wall tube made of high temperature alloys AISI 310.

The vessel includes multiple thermocouples and gas inlet and outlet fittings, granting

Standard test conditions.

Printing Tool - PC Software

The Printing Tool is a Windows© software that allows to print, save and store all data of performed tests. At the end of the test procedure, a new file is stored in the external memory USB stick. Test results are displayed in both text and graphical format. A spreadsheet layout is also available.

The printing feature of the Software allows to print out the test results as prescribed in the ISO procedures.

Specifications

| OVEN: | |

| Heating elements: | Silicon carbide elements (20 elements) |

| Heating Zones: | 5 heating zones |

| Max operating temperature: | 1200 °C |

| Maximum operating Power: | 20 kW |

| External thermocouple: | “K” type (inconel shielded) |

| Inner chamber diameter: | 140 mm |

| REACTION TUBE: | |

| Reaction tube type : | “Double wall” Type B |

| Material: | AISI 310 |

| Inner diameter: | 75 mm |

| Internal thermocouple: | Triple “K” type (inconel shielded) |

| GAS CONTROL UNIT: | |

| Flow rate measuring devices | Digital Mass Flow Meters |

| Reaction Gas flow rate: | Up to 50 nl/min |

| Purge Gas composition: | 100% N2 |

| Purge gas Flow rate: | Up to 50 nl/min |

| SAMPLE WEIGHING UNIT: | |

| Max weight: | 30 kg |

| Resolution: | 0,1 g |

| MAIN POWER: | 380 V 3 Ph + Neutral (20 kW max) |

Tumbler system TB 3000

According to ISO 4696-1, ISO 4696-2, IS 10823 and IS 8167, the sample is tumbled after the reaction in the oven. Number of revolutions is pre-set on a digital counter showing remaining revolutions to the end of tumbling. Automatic stop at end of test is provided. The units are protected by a safety cage with switch on the door. Please refer to the Tumbler System product page for further information.

Auxiliary Equipment

REACTION TUBE LIFTING ELECTRIC TACKLE

Reaction tube lifting tackle

• For insertion and removing of the reaction tubes

• Vertical electric movement

• Two controlled speeds – low / fast movement

• Manual horizontal movement on rail

• Max. weight 60 kg

• Remote control

• Rail included

• Power 230 V 50 Hz

REACTION TUBE TRIPOD

Reaction tube tripods

Model:

• TR 2000 – For CRI-RDI reaction tubes

REACTION TUBE COOLING DEVICES

|

Reaction tube cooling devices Reaction tube cooling devices |

• Digital Temperature controller

• Ventilation Fan

• Auto stop at preset temperature

• Power 230 V 50 Hz

Model:

-

CS 2000 – For CRI-RDI reaction tubes

Sample preparation devices

Auxiliary equipment for Sample Preparation can be provided together with main instrumentation.

Available devices are:

- Jaw Crusher for coke

- Sample Splitter

- Testing screen machine (with screening trays)

- Sieving Machine (with sieves)

- Sieves (for manual sieving)

- Thermostatic Oven

- Digital laboratory scale

RB Automazione Catalogue 2017

Download the RB Automazione general Catalogue 2017

Reviews

There are no reviews yet.